Plasma Spray Lab

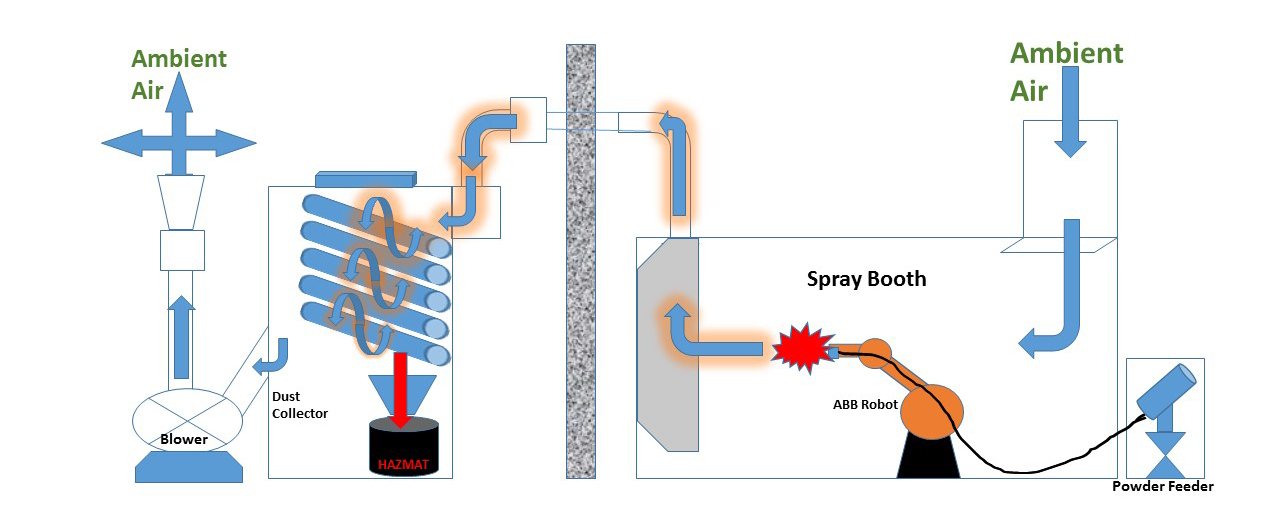

The Thermal Spray Laboratory at the Florida Institute of Technology (FIT) includes a Media Blast Cabinet, PRAXAIR Model 3710 Plasma Control System, PRAXAIR Model 1264 Powder Feeder, and the SG-100 Plasma Spray Gun for coating substrates with a variety of protective materials.

Advantages

- Versatility of modern equipment

- A wide range of materials (metals/ceramics/polymers) and any combination

- Mixed ceramics and alloys containing components with widely differing vapor pressures

- Homogeneous coatings without compositional changes across the thickness

- Microstructures with fine, equiaxed grain and without columnar defects

- Gradient coatings

- High deposition rates

- Free-standing thick forms in near-net shape fashion

- Any conceivable environment (air, reduced pressure, inert gas, underwater)

Description

Argon and helium gasses are utilized to serve as the preliminary plasma forming gas followed by hydrogen and nitrogen which increase the heat content and velocity of the plasma. The system is locally operated via the PRAXAIR Model 3710 Plasma Control System console which regulates power, plasma gas flow and cooling water, and sequences the parameters to initiate the process with precision and reliability.

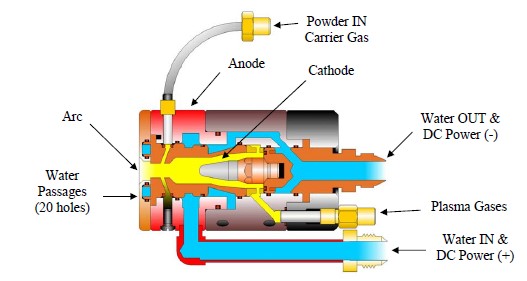

The SG-100 Plasma Spray Gun is comprised of a water-cooled copper anode and tungsten cathode. Plasma gas (argon, nitrogen, hydrogen, helium) flows around the cathode and through the anode, which is shaped as a constricting nozzle. The plasma is initiated by a high voltage discharge which causes localized ionization and a conductive path for a DC arc to form between the cathode and anode. The resistance heating from the arc causes the gas to reach extreme temperatures which dissociates and ionizes to form plasma. (Photos from PRAXAIR Operating Manual Rev H)

A complete air filtration system is in place which provides adequate airflow through the booth to prevent the buildup of combustible or explosive gases into the enclosed area ensuring safe operation of the thermal process.

Applications of Coatings

- Aeronautical and Space Industries

- Aero-engines, landing gear components, rocket thrust-chamber liners

- Automobile Industry

- Ceramics Industry

- Free-standing samples, Brick-clay extruders, Crucibles to melt oxide ceramics, ceramic membranes.

- Chemical Industry

- Photocatalytic surfaces, tools in petrol search installations, vessels in chemical refineries, gas-well-tubing, ozonizer tubes

- Energy Generation and Transport

- Solic-oxide fuel cells, thermopile devices for thermoelectric generators, boilers in power-generation plants, stationary gas turbines, hydropower stations, MHD generators.

- Iron and Steel Industries

- Continuous annealing line, continuous galvanizing section, stave cooling pipes

- Machine Building Industry

Give to Florida Tech

Give to Florida Tech