Florida Tech has the laboratories, instrumentation, computing power, etc. to serve the advanced coatings research, design, development, testing and production needs of small to large companies.

Thermal Spray Facility (TSF)

The TSF is equipped with a 100HE Plasma System which is locally operated via the 100HE Computer Integrated Thermal Spray (CITS) console which regulates power, plasma gas flow and cooling water, and sequences the parameters to initiate the process with precision and reliability.

High Heat Flux Facility (HHFF)

The CO2 PRC Laser Model STS3300 is configured to operate in the TEM00 mode at up to 1.6 kW with a peak temperature on the sample of 1700oC. Samples are heated from above by the laser and cooled from below by compressed cooling air. The top side temperature is controlled by modulating laser power output and the bottom side temperature is controlled by adjusting cooling airflow rate. The Laser Rig LabVIEW program controls the test rig and collects temperature data as well as laser power and cooling air flow at a 1 Hz rate, parsing the data into a configured Excel csv (comma separated values) file. A Cycle Status sheet Excel file is provided as a catalog of all the testing cycles.

Two types of laser thermal gradient tests are available: Soak Tests and Cycle Tests. The upper and lower sides of the test sample are monitored by off optical axis pyrometers. Video camera feeds monitor the laser status, test sample/component and pyrometers. The data from the pyrometers, the laser and the flow control valve is recorded into comma-separated-value data files for thermal analysis.

Metallographic analysis facility adjacent to the HHFF which allows sample preparation, tensile testing and hardness testing prior to microscopic analysis.

High Performance Computing (HPC)

The Blueshark cluster at Florida Tech is an IBM iDataplex system, comprised of 63 compute nodes (Total of 1,720 processor cores and 4,397GB RAM), 11 GPU nodes, 1 storage node and 1 head node. The Blueshark Cluster was funded by the National Science Foundation major Research Implementation grant. The HPC software environment is implemented in CentOS 7 Linux with a whole set of tools for numerical modeling development and commercial CFD and structure analysis packages. The HPC has dedicated personnel to support the campus users.

Center for High Resolution Microscopy and Imaging

A multidisciplinary laboratory with state-of-the-art light and fluorescence microscopy, transmission electron microscopy, scanning electron microscopy, scanning probe microscopy and x-ray microanalysis of natural and artificial materials.

Laser Additive Manufacturing (LAM) Lab

The LAM laboratory is a state-of-the-art laboratory equipped with a variety of continuous-wave (CW) and pulsed laser sources including a 2x 600W fiber delivered diode laser system (double-wavelength: l1 = 915 nm, l2 = 970 nm), 2x 300W Nd:YAG CW lasers (l= 1064 nm), a 240W CO2 CW/modulated laser (l= 10.6 µm), and 2x Nd:YAG ns-pulsed lasers (l= 1064 nm). All lasers can be coupled with one of the three industrial workstations each featuring a 2D or 3D Aerotech positioning system, beam guiding and focusing optics and control units.

Other equipment includes a galvo-scanner, industrial fume extraction equipment, shield gas supply infrastructure, process chambers, and a set of process diagnostics. The LAM laboratory will be the primary facility for the development of the proposed LMD unit in this effort.

Machine Shop

A working machine shop with CNC and welding capabilities.

Ultrafast Laser Materials Processing (ULMP) Lab

The ULMP lab uses femtosecond and picosecond lasers with various pulse durations (tp), repetition rates (frep) and pulse energies (Ep): Amplitude Satsuma (tp=500fs, frep = 0.1..5 MHz, Ep=10 µJ), Spectra-Physics Spitfire (tp=100 fs, frep=1 kHz, Ep=1 mJ), Lumera SupeRapid (tp = 10 ps, frep=10..640kHz, Ep=250 µJ), and 2x Lumera Staccato (tp=2.4..10ps, frep=80 kHz, Ep=50 µJ).

Positioning equipment includes several high-precision 3D stages (Aerotech, Newport, ALIO), and several workstations equipped with micro-focusing equipment.

An extensive set of process diagnostics is available to acquire time- and space-resolved process data using high-speed cameras, and pump-probe experimental setups.

Fourier Transform – InfraRed Spectrometer (FT-IR)

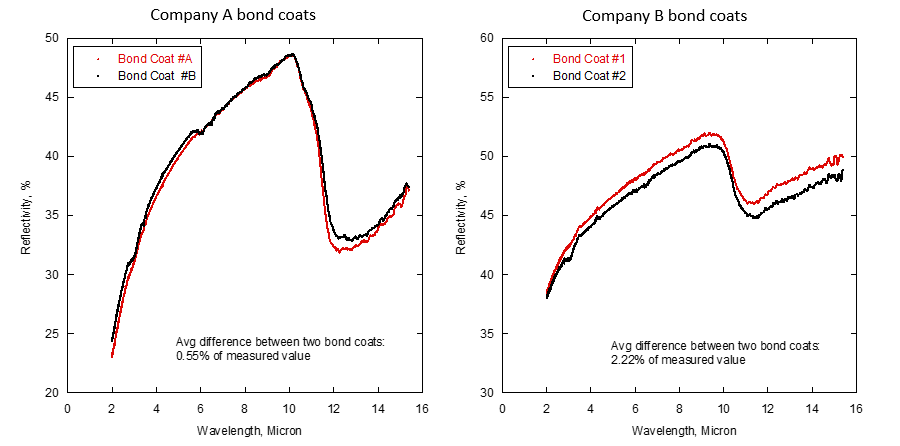

The CAC recently acquired a Nicolet iS50 Fourier Transform InfraRed (FTIR) Spectrometer. The instrument will provide a broad range capability of material analyses. For coatings study, CAC can examine the spectral reflectance and transmittance of coatings to ensure the quality and consistency from the manufacturing processes (APS or EB-PVD).

- Most molecules have their rotational-vibrational energy transitions occur in the IR spectrum. Analyzing the IR spectra of absorption, transmission, or reflection can determine material’s composition and purity in solid and liquid phases. With additional accessories, gas phase can be analyzed as well.

- FTIR spectrometer instrument is often used to inspect specimen spectral characteristics for purity, quality control, etc.

- Ceramic coatings (or ceramic oxides) have, in general, specific refractive index n ̂(l) dependence on the wavelength. The voids, porosity, and n ̂(l) of a given coating will lead to unique spectral absorptance and reflectance curves in FTIR spectroscopy measurement.

Illustration: Radiative properties (R & T) are a function of coating composition, surface roughness and porosity.

Give to Florida Tech

Give to Florida Tech