Florida Tech has the laboratories, instrumentation, computing power, etc. to serve the advanced coatings research, design, development, testing and production needs of small to large companies.

High Heat Flux, High Temperature Gradient Laser Rig

The CO2 PRC Laser Model STS3300 is configured to operate in the TEM00 mode at up to 2 kW with a peak temperature on the sample of 2000oC. Samples are heated from above by the laser and cooled from above and below by airjets. The top-side and bottom-side temperatures are controlled by modulating the laser power output and the cooling airflow rate. The Laser Rig LabVIEW program controls the test rig and collects temperature data as well as laser power and cooling airflow at a 1 Hz rate. The temperature data and top/bottom side temperature distributions are collected by IR pyrometers and IR cameras.

Two test modes of temperature gradient thermal cycling are available: constant temperature mode and constant power/flow mode.

The laser rig can produce uniform, Gaussian, and any specified temperature distributions on the heated surface. We have extensive testing experience on TBC and EBC samples and engine components.

Metallographic analysis facility adjacent to the laser rig allows sample preparation, tensile testing and hardness testing prior to microscopic analysis.

Center for High Resolution Microscopy and Imaging

A multidisciplinary laboratory with state-of-the-art light and fluorescence microscopy, transmission electron microscopy, scanning electron microscopy, scanning probe microscopy and x-ray microanalysis of natural and artificial materials.

Machine Shop

A working machine shop with CNC and welding capabilities.

Fourier Transform – InfraRed Spectrometer (FT-IR)

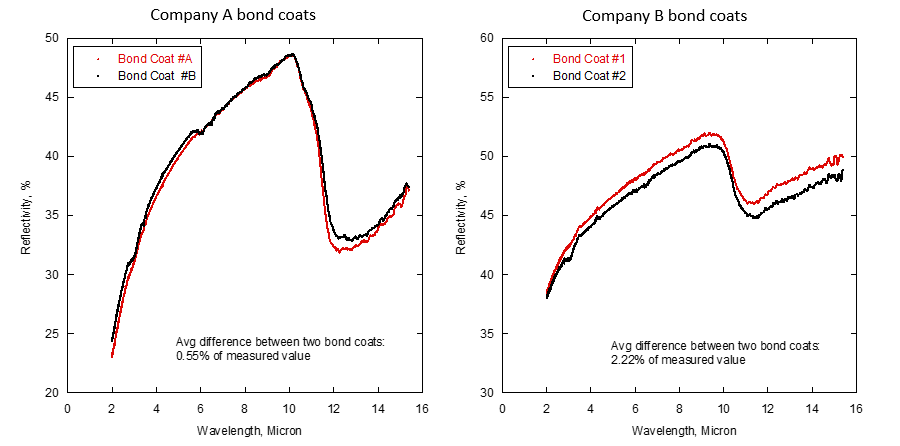

The CAC recently acquired a Nicolet iS50 Fourier Transform InfraRed (FTIR) Spectrometer. The instrument will provide a broad range of material analyses. In coatings studies, CAC can examine the spectral reflectance and transmittance of coatings to ensure quality and consistency across manufacturing processes (APS or EB-PVD).

- Most molecules have their rotational-vibrational energy transitions occur in the IR spectrum. Analyzing the IR spectra of absorption, transmission, or reflection can determine a material’s composition and purity in solid and liquid phases. With additional accessories, the gas phase can be analyzed as well.

- FTIR spectrometer is often used to inspect specimen spectral characteristics for purity, quality control, etc.

- Ceramic coatings (or ceramic oxides) have, in general, a specific refractive index nl dependence on the wavelength. The voids, porosity, and n of a given coating will lead to unique spectral absorptance and reflectance curves in FTIR spectroscopy measurement.

Illustration: Radiative properties (R & T) are a function of coating composition, surface roughness and porosity.

Give to Florida Tech

Give to Florida Tech